Is Polystyrene Recyclable?

Yes, Expanded Polystyrene (EPS) can be recycled and is recycled up and down the UK and around the world. It is one of the most efficient and cost effective insulating materials on the planet. Its low rate of thermal conductivity makes it super reliable for transporting temperature sensitive products.

Feel free to share this web page with your customers.

-

100% Recyclable

Not many people know that EPS is 100% recyclable. Clean material can be reused in the manufacturing process of new poly boxes. Any slightly contaminated material can be compacted and turned into recycled rigid plastic products.

-

EPS is 98% Air

Expanded Polystyrene is very similar to a party balloon because what you see, when you look at a piece of EPS or a balloon is only the 2% of what makes up the items final shape. The 98% of the object that you do not see is thin air!

-

EPS has an ODP of Zero

EPS has an Ozone Depletion Potential (ODP) of zero and causes no damage to the ozone layer because no CFC’s or HCFC’s are used during the manufacturing process. EPS is inert, does not leach any chemicals and is completely food contact safe.

Why is Polystyrene a Good Insulator?

-

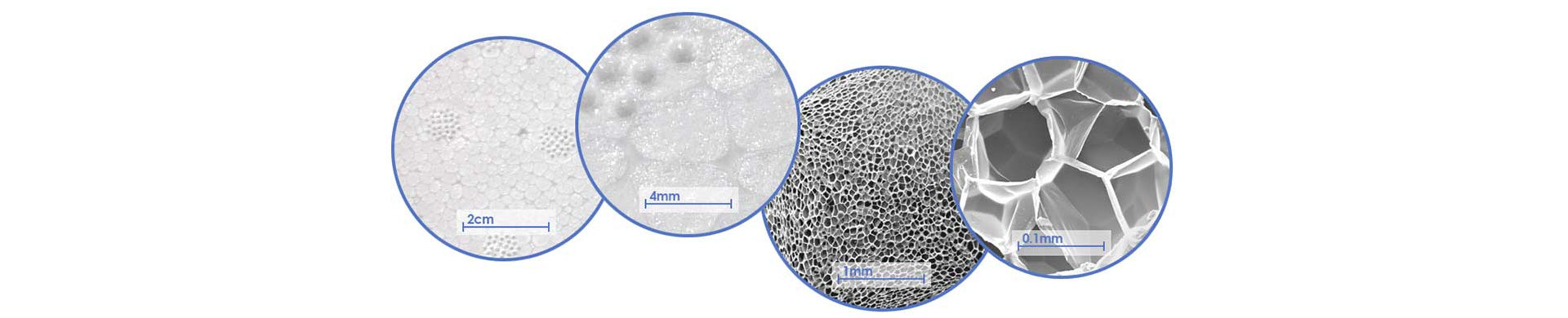

Expanded Polystyrene is an effective insulator because it's packed full of tiny air pockets. Air is a very poor conductor of heat so heat transfer is minimised.

-

EPS is a closed cell foam, meaning every cell is closed off to the other cells that surround it. The cell walls help to provide rigidity to the material and trap air inside.

-

Move closer and you start to see the inner structure of the individual EPS beads.

-

Move even closer and you can see the microscopic walls that trap the air. There can be as many as 16,000 cells (air pockets) per bead of EPS.

Other uses for a Polystyrene Box

Unable to recycle polystyrene? Time to consider ways to re-use your poly boxes or switch to a deluxe reusable box instead.

Reuse ideas for polystyrene boxes!

Polystyrene boxes are 100% recyclable and are designed to be highly durable. To prevent boxes going to landfill unnecessarily consider some alternative uses:

- A cool box for picnics and drinks

- A big bedding tray for seed germination

- Growing root vegetables in small spaces

- Break up to aid drainage in plant pots

- Homemade chick brooder

- Homemade food hampers for friends at Christmas

- For freezer contents during defrost or house move

- Chick, snake and reptile egg incubators

- A homemade hedgehog house

Polystyrene Recycling Case Studies

-

Dixons Carphone: Launch Nationwide Polystyrene Takeback

Find out moreDixons Carphone, the parent company of brands like Currys and PC World, has committed to ensuring all its own-label products are either reusable or recyclable by 2023.

-

John Lewis Collection of Customers’ White Goods Packaging

Find out morePair text with an image to focus on your chosen product, collection, or blog post. Add details on availability, style, or even provide a review.

Sustainability Benefits of EPS

-

Resource efficient

Expanded Foams like EPS demonstrate an efficient use of natural resource. The manufacturing process uses very little energy and it only takes steam and pressure to fuse the aerated beads together.

-

Keeping your warm

Throughout the building industry EPS insulates keeping our homes warm, energy bills down and lowers emissions to ease our depletion of the earth’s natural resources.

-

EPS Life Cycle

EPS moulding does not pose any risk to human health or the environment. Lifecycle analysis has shown that EPS has far less of an environmental impact than other materials with the same use.

Where can polystyrene be recycled?

Unfortunately local authorities are not able to collect kerbside recycling of EPS due to the lack of required recycling infrastructure unlike paper fibre and glass. As a business we are focussed on helping to fill this gap by offering clean EPS recycling drop off points at our manufacturing sites.

There are two methods of recycling used EPS at our sites:

EPS Granulation

Lighter densities of material go through a granulator that regrinds the material back in to beads, granulate is stored in silos mixed with virgin material and dosed back into the production without any detriment to the quality of the finished EPS product. JB Packaging is part of Engineered Foam Products, we can take any clean EPS waste (including JB Packaging poly boxes), scrap and off-cuts and recycle it back into the production process in as little as 2 hours.

EPS Compacting

Densities heavier than 28g/l with minimal contamination can be compacted and turned into super dense bales that can be easily palletised and shipped more economically by lorry load. These EPS bales are then processed and converted in to clean General Purpose Polystyrene Pellets (GPPS).